Copyright ©2018 Shanghai Anto Information Technology Co., Ltd. 沪ICP备08114470号-1

Solution

基于AR的远程维修解决方案

basic information

Experience manufacturing, create the future - antau intelligent AR technology research and application

In the general trend of economic globalization, almost every country is in the market of global competition, and economic competition is the competition of manufacturing technology and manufacturing capacity in the final analysis. Who has mastered advanced manufacturing technology, who can produce high level products, who has mastered the market, who can be in an invincible position in the competition.

Driven by economic globalization and information technology, the mode of production of international manufacturing industry is undergoing significant changes. In recent years, major industrial countries have formulated their own development plans to promote the transformation of traditional manufacturing industry into advanced manufacturing industry. Accelerating the development of advanced manufacturing has become a new trend of the world manufacturing industry. Model-based enterprise (MBE) has become the embodiment of modern advanced manufacturing system, representing the future of digital manufacturing. The U.S. army research institute (arri) states that "the ability to build enterprise mbes properly can reduce non-recurring costs by 50 to 70 percent and reduce time-to-market by up to 50 percent." Based on this, many manufacturing enterprises in the United States and even the world gradually join the MBE enterprise construction army.

However, digital enterprise (MBE) brings challenges to PLM downstream:

How does 3D data extend to the site

How to record and supervise the execution of process instructions

Integrate processes to enhance experience and prevent errors

How to achieve remote expert "site" guidance

How to combine mass data and site seamlessly

How to avoid visual detection error

How to simplify the testing process and improve the experience

How to combine 3D model to realize automatic data collection

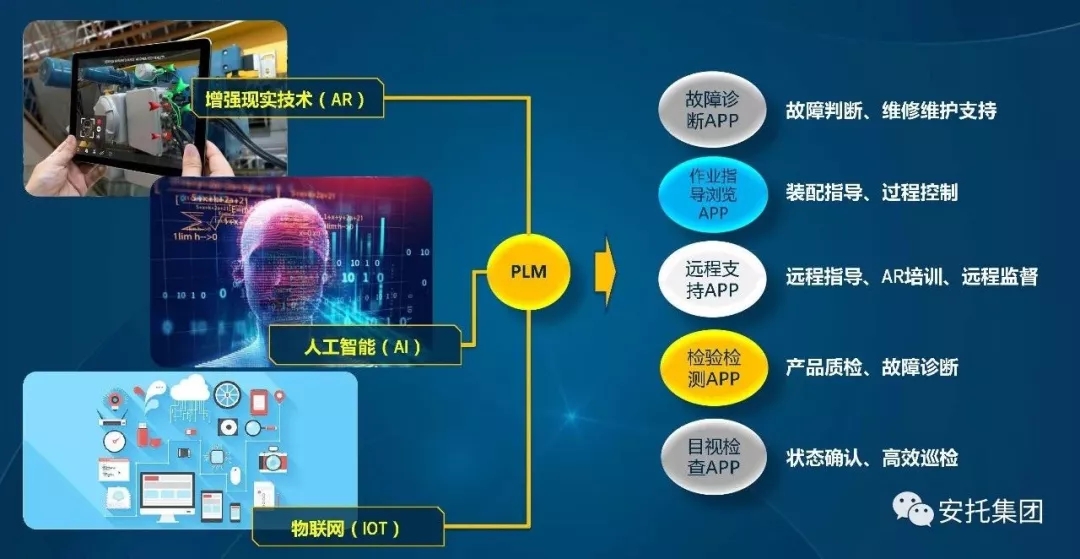

The company will integrate three technologies, augmented reality (AR), artificial intelligence (AI) and Internet of things (IOT), to launch an AR based remote maintenance solution. The solution can also be integrated into PLM systems to use 3D models from PLM systems for AR demonstrations. As long as you wear glasses, you can get any you want, any you want to see, through AR technology, guide us to complete the impossible task, to help you create a more novel, more timely, more effective, lower cost service model.

Feature 1: model-based highlighting

Field engineers describe problems to remote experts via real-time video and voice;

The remote expert selects a part on the 3d model, and the field engineer sees the real part and highlights it accordingly.

Remote experts can check the maintenance process of field engineers through real-time video.

Function 2: send CAD drawings

The remote expert can send the CAD drawing to the field engineer.

Function 3: internal structure view and text send

Through the analysis model, the remote expert can send the internal structure of the maintenance object to the physical object on the site for the site engineer to check.

The remote expert can send the text information in the maintenance manual to the field engineer.

Field engineers can zoom in and out of holographic images by voice.

Function 4: circle based on real environment

Remote experts can directly add annotation on video reflecting the real-time status of the site, and field engineers can see the annotation information in the corresponding position of the real object.

On a

Antuo Project Management System